In May, a group of 13 US softwood lumber suppliers and trade association representatives participated in a week-long trade mission to Monterrey and Tijuana organized by the Softwood Export Council (SEC). The group met with wooden pallet and packaging producers and importer-distributors during visits to manufacturing facilities and distribution yards. Over 65 importers and manufacturers also attended seminars and receptions where speakers presented information about US softwood lumber grades and trends affecting US softwood lumber availability and competitiveness in Mexico. Mission participants rated the mission highly. Preliminary sales reported within one month of the mission totaled $670,000 and companies project $4.16 million in sales by the end of 2023.

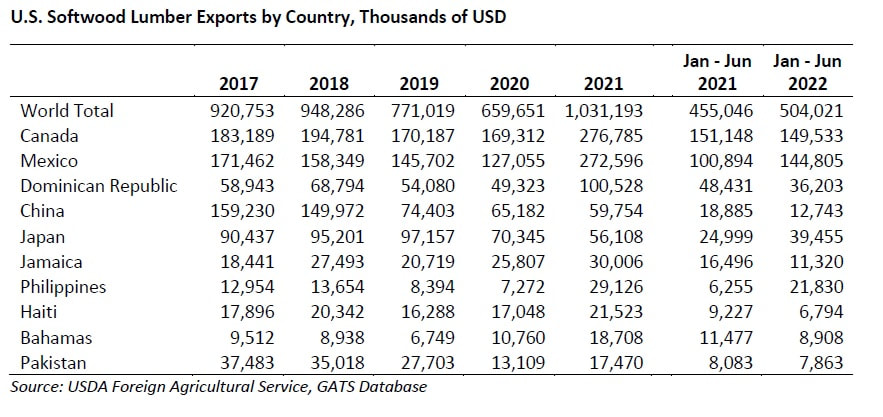

Demand for US softwood lumber to Mexico is increasing at an unprecedented rate. A number of factors are contributing to this trend including Chinese manufacturer nearshoring, low labor rates, limited domestic lumber supply as a result of cartel related violence, positive impacts of the US-Mexico Canada Agreement (USMCA), and the logistical advantages of a shared border with the US. Years of education about US species have also paid off with Mexican producers reporting that they prefer the characteristics of US species to domestic or South American species. From 2017 to 2022, US softwood lumber exports to Mexico increased 66%, far surpassing growth in any other market. Mexico is now the number one international market for US softwood lumber, totaling $282 million in 2022.

SEC will hold a follow up mission to Mexico in April 2024. See SEC's international events calendar for more information.

Demand for US softwood lumber to Mexico is increasing at an unprecedented rate. A number of factors are contributing to this trend including Chinese manufacturer nearshoring, low labor rates, limited domestic lumber supply as a result of cartel related violence, positive impacts of the US-Mexico Canada Agreement (USMCA), and the logistical advantages of a shared border with the US. Years of education about US species have also paid off with Mexican producers reporting that they prefer the characteristics of US species to domestic or South American species. From 2017 to 2022, US softwood lumber exports to Mexico increased 66%, far surpassing growth in any other market. Mexico is now the number one international market for US softwood lumber, totaling $282 million in 2022.

SEC will hold a follow up mission to Mexico in April 2024. See SEC's international events calendar for more information.